BIG D IS HERE

Are you ready? (Infra magazine 2/2016)

Digitization has come here to stay. It’s not just a small jump, it’s a big leap – if you haven’t taken the first step yet, now it’s time to hurry. Jump in and claim your place under the Big D sun.

Text by Sari Okko, translated by Nina Aro & Pipsa Aro, Infrakit

Chairman of Andament Group Matti Juola knows that. The concept of digitization is pushed from all forums, but it is still unclear and distant to many. Hyping it can be even annoying.

“It’s not a bogeyman, but the concept may be difficult to understand. When at work your hands are full and feet deep in clay, it’s challenging to get on top of the digitization wave,” Juola admits.

Despite prejudice and vagueness it’s better to start getting digital today rather than tomorrow or next week. “Even though you might feel like pushing it aside and out of mind, it’s not possible anymore”, says Juola.

Get it Done, but How?

“It’s most important to approach it consistently. Start researching it, get information, reserve some time and simply just think what it’s all about, what to do and how much, how and for how long, and what it generally means”, Juola answers.

“It is obvious that not every company needs to be on the crest of the wave but all of them should think what digitization, automation and robotisation could mean to their business. Everything depends on the management. Digitization should become a part of the strategy and business planning. You can’t outsource this job thinking that digitization is just about IT, devices and software that previously was simply ordered and bought from a store.”

“In infra-construction digitization as an issue is bigger and more complex than just buying a new excavator. Digitization is inevitably and increasingly working its way into everyday work, changing job descriptions and making some activities unnecessary.”

Juola recommends to roll up your sleeves. “When you take your time adopting digitization and think about the strategy carefully, you won’t find yourself rushing hurryingly through it.”

Do We Need New Digital Management?

According to Juola, digitization concerns companies of any size and the entire work community. New type of “digital management” is not completely necessary if change management is prepped with fresh insight on digitization viewpoints.

Relevant expertise is not always found in-house, even if company was filled with seasoned specialists. It’s not easy to adopt new views and working methods if you are used to doing things traditionally.

“For startups it’s common to consult Senior Advisers, but in case of digitization, companies should ask for Junior Advisers’ vision and knowledge”, Juola contemplates.

Juola doesn’t think digitization is only for the young, even though “facsimile and email generation” sees “Social Media generation” as the digitization age group. “In times of change you need new expertise, but it doesn’t mean older generation couldn’t learn new methods. Nowadays you must continuously update your expertise.”

First Big Companies, Then the Small?

During his career Juola has seen many trends come and go. Digitization is not one of the shooting stars or a passing phenomenon. “Change is constant and there is no going back to old”, assures Juola.

In infra-construction the spectrum of digitization expertise is now as wide as companies themselves. When some are taking digital leaps, others are just learning how to use email – roughly speaking. “Some bigger companies are already on the crest of the digitization wave which is a great thing. Actions of big companies open doors and create awareness and attractiveness for smaller players as well.”

Juola calls for open-mindedness and focusing on entities. “We Finns tend to get excited and rush into smaller things without seeing the big picture. In practice we need enough firepower to get into new markets. New business will eventually need to be seen in the financial results.”

What’s the Point of Big D?

Construction industry already benefits from digitization. It means that the 565 billion euro industry has a chance to stand out and improve its productivity and competitiveness. Surge in productivity due to digital leap is a big opportunity for the economy.

Juola wants to bring out the opportunities of digitization and clear the way for its progress.

“Digitization provides customers with comprehensive service and adds value to the products. Digitization reduces manual logs and mistakes, automates routine tasks like calculation, data recording and processing. Digitization simplifies processes, streamlines operations, and adds transparency and opportunities for tracking and measuring activities in real-time. Productivity and effectiveness improve when you can do more and better quality with the same resources. Drafting new business models can be difficult, but it’s worth to dig and try out different opportunities. With the right attitude and openness you can get pretty far.”

Mobile in the Field

Nevia’s (part of Andament Group) mission is to make transportation safer with modern technology: by measuring the amount of traffic, analysing traffic jams and condition of pavement, and developing smart traffic services and software.

The company has experience in providing road services for the Finnish Transport Agency, Centres for Economic Development, Transport and Environment, municipalities and individuals. Their core expertise is mobile “asphalt pavement quality control measuring” which they implement thousands of kilometres of measurements a year.

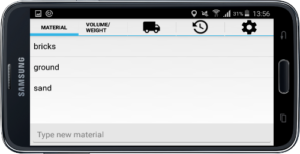

“Nevigator system is developed to record terrain observations. It all started because we needed a mobile tool for terrain workers. We focused on usability, business agility, improving cost-efficiency and simplifying operations”, Juola explains.

“With this system the whole organisation receives prompt observations on road surface friction, damaged pavement and broken light or safety devices. Information about water slot depth and road surface slope helps prioritizing maintenance projects.”

Matti Juola urges us to try out digitization already today than tomorrow. Being too busy is not enough of an excuse.

You can use Nevigator on desktops for example in quality control of winter maintenance.

Nevia’s Nevigator data collection system is used in road maintenance planning and real-time quality control.

Even the Ancient Greeks said…

“The secret of change is to focus all of your energy,

not on fighting the old, but on building the new.”

-Socrates

Examples from the World of Big D

How does digitization break the old ways – or does it? Why should we take the leap? We asked from those who already are far with it.

Case Infrakit: Die Like Dinosaurs or Go Digital

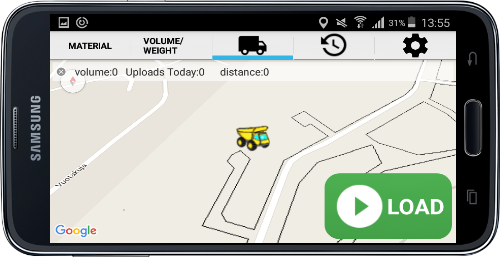

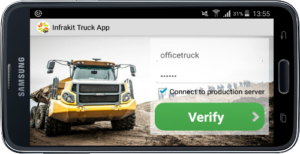

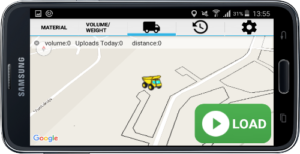

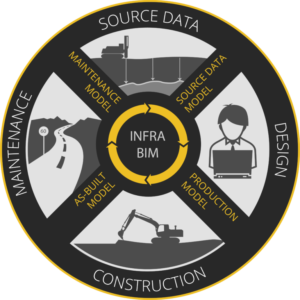

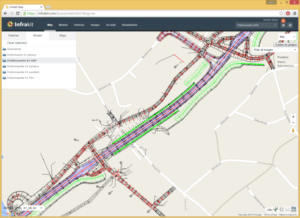

“Infrakit is an infra-construction collaboration cloud that makes the worksite digital so that all data is shared in real-time so that all work machinery and people are always up-to-date”, says Teemu Kivimäki, the CEO of Infrakit.

“With Infrakit planning, spotting and resolving problems on the site, resourcing and scheduling improve significantly – and we have proof of that. Those construction companies that already utilize BIM in their projects got rid of construction errors and now build correctly on the first try. The difference to the old methods is impressive. Working with paper is not enough anymore. Nowadays 3D models are crucial because they allow us to utilize the data we get back from machine control systems and other measuring equipment. A work machine with 3D machine control and real-time Infrakit cloud is also always on the map. We have noticed that work performance improvement in these cases is 40% higher compared to traditional methods, a.k.a. working “in the darkness”.

According to Kivimäki we have only just witnessed the beginning of digitization in infrastructure industry. “Definitely seems that companies that aren’t yet on board of digitization will get extinct like dinosaurs.”

Infrakit Cloud connects all devices on the construction site in real-time.

Infrakit is a digital system for efficient project management in infrastructure construction.

It is also the winner of Finnish Quality Innovation of the Year 2015 competition and came second in the same category in the International Quality Innovation competition.

Case Tietomekka: Ditch the Unnecessary and Get Efficient

“Digitization changes infrastructure industry work methods in many ways, and challenges learning. The ones who resist change in the beginning usually notice the benefits and competitive advantages later, too.” says CEO of Tietomekka, Keijo Pulkkinen.

“We have been recognized for our innovativeness and business enabling software and services that benefit customers through growth in efficiency, savings and customer service development. Autori software is based on wireless data transfer, geolocation and map-based data management including apps for on-site and office use at different phases of a project. Digitization improves collaboration and efficiency for contractor activities and adds value to their operations.”

“Employees can concentrate on their core expertise when there is less unnecessary work, like data gathering and reporting.”

Digitization is already an important part of road marking. It makes work more efficient, saves time and money, and develops collaboration.

Case Lemminkäinen: From Data Hunting to Data Management

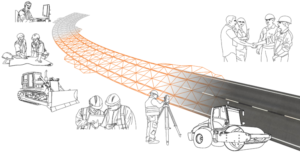

“When information is shared between software and from an office to another and/or to worksites, design and construction quality improves, communication is easier and there are fewer mistakes” says Kyösti Ratia, the Technical Manager of Lemminkäinen Infra Ltd.

“For example, the wasting of resources has reduced because of improved work quality, thanks to machine automation. Over-digging has decreased, which means less filling and less work for dump trucks. The use of IM3 format has improved surveying quality and changed land surveyors’ work content.”

“As an example I can mention a worksite, where fuel consumption of excavators increased circa 30% – they were simply working more because they didn’t have to wait for measurements to be implemented. Now excavators work more precisely – tolerances are just within few centimetres compared to the previous 10-15 cm. Traditional data hunting and data “dumbifying” should be in the past. You have an access to years of planned work, gathered data and solutions – so why only the tip of the iceberg is taken to the next level?”

“The challenge is data reliability. You can find the person responsible for it – and for work safety – by taking a good look in the mirror.”

Case VR Track: Activist, follower or avoider?

“Digital revolution affects all organisational and personal levels – from managers to railway track workers”, says the Development Manager of VR Track Ltd Jouni Kekäle.

“In every-day life digitization can be seen, for example, for railway track workers that they now use mobile apps and GNSS devices instead of rods. In infra-construction industry there are several projects where BIM clearly improved productivity, e.g. Lielahti-Kokemäki track project, Pisararata design, Tampere tram project and Äänekoski factory accessibility track project.”

“The question now is how to take part in the digital revolution – being proactive, follow others or just avoid it? Opportunities and risks will result according to the role you have chosen. Being a follower or avoider ends up badly. If you want to stay competitive you have to jump on top of the digitization wave in one way or another. Also, it’s not enough just to acquire new digital devices and apps for the worksite, you have to invest in personnel training and implementation too.”

“Digitization has become the core of our strategy. We want to be active in the frontline of the industry development, which requires us to be unbiased, agile and open to try new things.”

Source: INFRA – Infra Contractors Association in Finland, infra.fi / original article appeared in Finnish for Infra magazine, infra.fi/lehti

Recent Comments