What is meant by digital infrastructure construction?

What is meant by digital infrastructure construction?

Infrastructure construction has been considered a low-tech field, but significant changes have taken place in recent years. Due to the development of work machine automation technology in the 2000s, traditional land building production method shifted from digital 3D models into implementation before anybody even talked about digitalization. The leap in the 2010s is largely based on the development of consumer and cloud service technologies, as well as on infra construction applications capitalizing on the aforementioned. We now process infrastructure information models on mobile devices and monitor production in real time. During the past five years Destia has had approximately 50 construction projects annually that are being carried out utilizing information model designs and 3D machine control systems. We are on the forefront of digitalization in our industry.

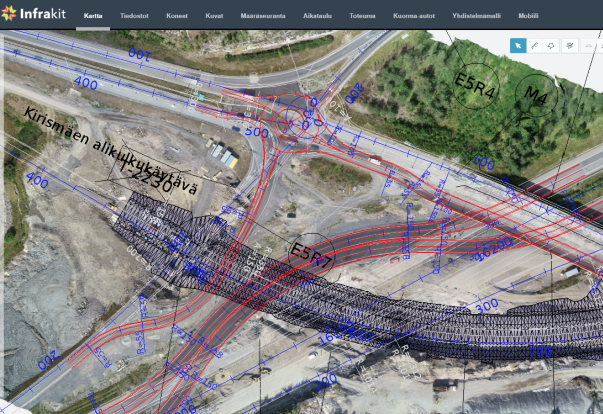

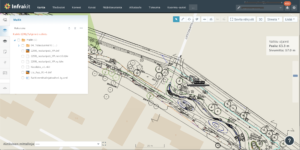

Destia is a pioneer in model-based production, where digital road models and designs of earth

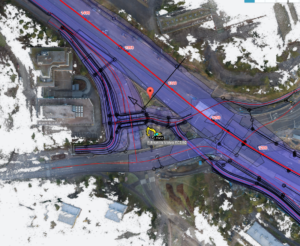

structures drawn up by designers are being transferred into production with construction machine control systems. The machines have an enhanced satellite positioning and 3D-contolling system, which the machine operator can use for high-accuracy constructing using 3D models. This method increases performance, improves quality and reduces material wastage. The designs, in other words, information models are being managed and shared by the machines through a cloud service, where the management and clients can examine the models and stay up to date on the progress of the projects.

A couple of years ago Destia started to develop and pilot a method of producing digital handover material during construction to replace the traditional quality documentation method done at the end of a project and to enable utilizing the materials in model-based systems in the future. Since then this method has rapidly gained a foothold in our projects. It was described in the Finnish Transport Infrastructure Agency’s infra model guidelines in 2017 and as a part of the Common InfraBIM Requirements of 2019, where the method has been refined and also included in earlier stages of infra projects requiring information exchange.

In Destia’s large-scale projects the model-based method is always implemented as thoroughly as possible and its features are continuously being developed. For example in the Vt 4 Kirri-Tikkakoski project the designs for dozens of bridges will go through the inspection and approval process of designers, construction management and the client entirely in a model-based method. This is being carried out for the first time in a project of this magnitude in Finland. Diverse utilization of drones as part of the model-based process has quickly become a part of the everyday procedure in all of our large-scale projects. Collecting and refining production data from separate sources has reached a new level, as comprehensive information about production is available via automatized analytics on project level as well as on company level.

The infra construction industry is, in fact very keen to benefit from new possibilities offered by digitalization, and individual leaps in development can be implemented in an agile fashion. For example VR headsets that we know from the gaming world have given a completely new dimension to understanding construction sites with an information model. In the future VR and AR headsets might very well become standard equipment on construction sites – the same way mobile devices are now used in examining information models and in documentation, utilizing positioning accuracy to centimeter level if necessary. At the moment it seems, however, that of all new construction site technologies the use of drones is growing most rapidly.

The notion of infra construction as an industry that is rigid and slow to develop can surely be discarded. The foundations for a new kind of digital infra field have now been created – the future will show where this development will take us.

Pasi Nurminen is the R&D Director of Destia Ltd. This blog is updated, and it was published earlier on destia.fi (in Finnish).

Pasi Nurminen

September 30, 2019

Book a Demo

Discover how Infrakit connects your entire infra project operations and drives value to every part of your business.

Recent Comments