“These Two Things Must Change for InfraConstruction to Become Sustainable” – Eija Multanen, Sustainable Construction Expert

These Two Things Must Change for Construction to Become Sustainable – Eija Multanen, Sustainable Construction Expert

We interviewed Eija Multanen, an expert in the infrastructure construction sector, regarding the goals and actions towards carbon neutrality in the industry. Eija serves as the Sustainability and Risk Manager at AFRY, a company focused on promoting multidisciplinary responsibility and sustainable development. She is also leading the sustainability team for the internationally significant construction project, Kalasatama-Pasila, from a responsibility perspective.

Eija, what do the trends in advancing carbon neutrality in the infrastructure construction sector look like for the next five years?

That’s not an easy question to start with, but maybe if we reflect on what has been achieved in the Kalasatama-Pasila project over the last five years, the use of low-carbon concrete has progressed significantly and will certainly remain important in the future. Of course, we’ve only used it for the slab foundation so far, which is just a single structure, but perhaps in the future, it will be applied more broadly as manufacturers have gained a lot of experience. And then, in the bigger picture, the transition from a linear to a circular economy, even though it’s an old trend and there are many challenges in implementing it, but I believe that developing solutions for this will achieve a lot.

Let’s pretend you were given omnipotent powers. What three changes would you make in the infrastructure construction sector to achieve our carbon neutrality goals?

First, we should probably simplify the permitting processes, which make the transition heavy and difficult for operators. Of course, it’s not easy, but if we’re pretending to have omnipotent powers, that’s something that should be fixed. Then, I’d probably switch all machinery to electric. Again, easier said than done, as this involves many factors from different fields, but an electric machinery fleet would indeed be a big leap towards carbon neutrality. It would likely also have positive effects on other sectors, as more battery factories could be established in Finland if we had a leading market here. Maybe instead of three, I’d just make these two changes.

Let’s take these two then. If we look at these, electrified machinery and simplified permitting processes, what do you see as the challenges that are slowing down the change we need?

The cost of investments is significant, and sharing that risk alone is not possible for any contractor or operator. In addition, there is a lot of outdated information in the field, even among top performers, so perhaps, cliché as it may sound, continuing and intensifying cooperation is what we need. It would require almost a systemic change, where financial risk could be shared, requirements tightened faster than currently, and knowledge continuously and rapidly shared.

Thank you, Eija, for your responses. Would you like to send any final messages to the professionals in our field?

To freely paraphrase Albert Einstein, ‘You cannot keep doing the same things in the same way and expect a different outcome than before.’ Good new practices and experiments are already being implemented, but surely everyone can think even more about whether they can take that bold step that helps everyone move forward?

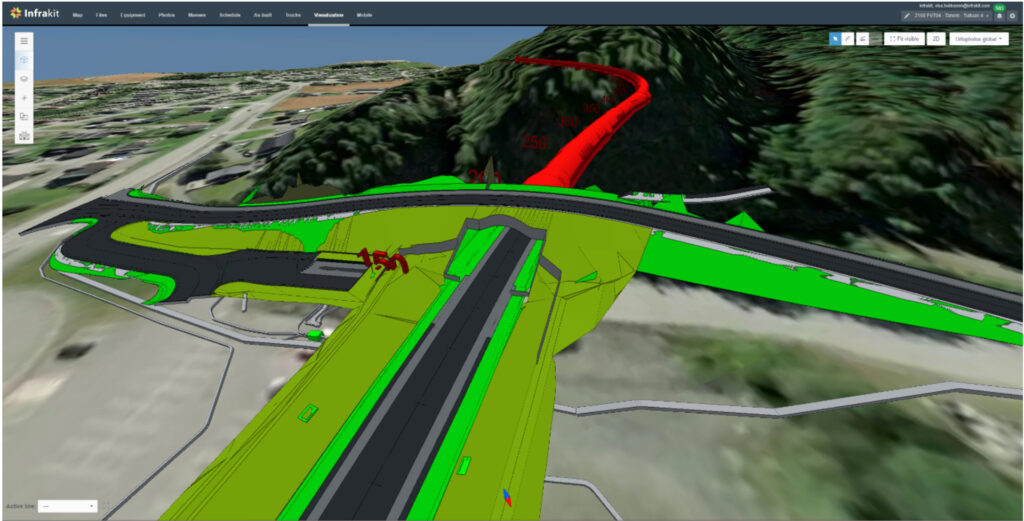

Book a Demo

Discover how Infrakit connects your entire infra project operations and drives value to every part of your business.

Recent Comments