6 principles for infra-collaboration

6 principles for infra-collaboration

The future is exponential

For the first time in human history we live in an exponential world. Moore’s Law, which say that every 1-2 years the number of transistors per square inch on integrated circuits doubles, creates an exponential development for anything digital. Up until recently humans have lived in a linear world. Linearity is predictable and understandable, and most of our systems are developed around a sort of linear change.

How does this exponential world affect the infrastructure industry?

Well, at least it will not be predictable. Development will happen at a higher pace and new methods will be available that will transform the way we work.

What will be the key to success?

When change happens fast and new methods become available the key thing we can do is collaborate. Having information available in real-time will have a huge impact in how we make decisions. Consider a worst case for example: imagine not visiting the construction site for 1 month and not knowing what has happened there the last 4 weeks? How would you feel?

Having information available in real-time will have a huge impact in how we make decisions.

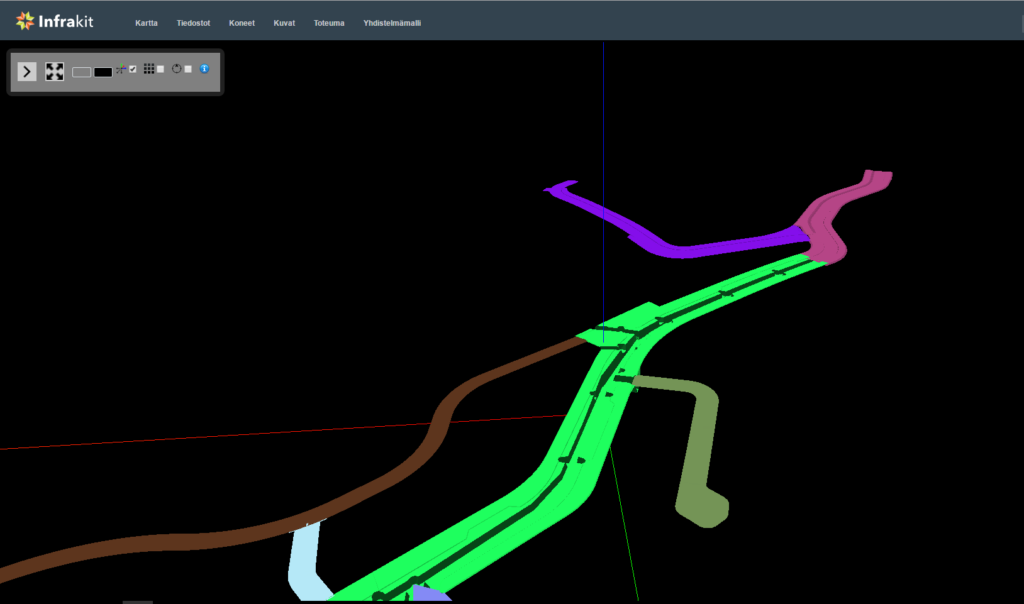

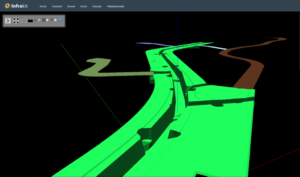

Real-time view of the project status

Well, then imagine having a real-time view of your site, from anywhere. On your commute home from work you can see that, yes, they did complete that last part. And yes, it has been documented to be proved as planned. That’s a good feeling. Also when errors do occur, having the chance to detect and avoiding them in real time, not 2 weeks later, is a great feeling.

How can we make sure information is available and that communication happens the way it should?

Well, we have proposed the “6 principles for infra-collaboration”. As described below these are the foundation of how you make sure your personnel have access to up-to-date information about your project. And having access to information is the best indicator that your project is on its way to success. Especially in an exponential, unpredictable and fast changing world of infra.

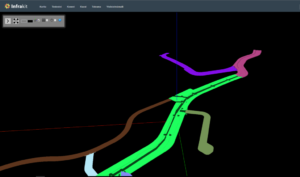

Cloud-connected in open formats – availability for all in real-time

“6 principles for infra-collaboration”

1) Use open file formats

Because if you use proprietary formats for exchanging information there will be a day when someone can not access the info. Also, open formats allow you to use the tools and software you or your sub-contractors prefer.

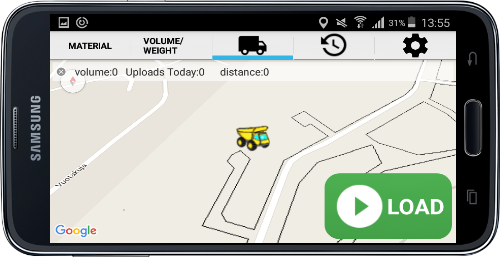

2) Support different equipment, machines and hardware

So that you are free to use the equipment you like, and for example negotiate on price. This is an important thing for the bottom line of the project.

3) A collaboration tool can not also be a CAD tool

Use different CAD tools, each tackling their own task. You should have the option to solve different tasks with different tools. And if you hire a new member of staff or consultant, they should be able to use the tools they have skills for.

4) Have the same files and information available both on site and in the office

Because having to print or create a copy of the file to bring out to the site is a waste of time.

5) Have information available on all platforms: mobile, tablet, PC/Mac

Because you should be free to choose which computers and mobile devices you want to use.

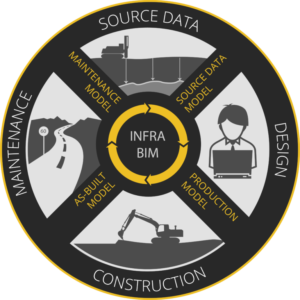

6) Support information flow between all project phases: designing, construction and as-built documentation + maintenance

Because for each time you change systems you lose a little bit of information.

Read more on the subject: “Infra-construction in 2020”

Book a Demo

Discover how Infrakit connects your entire infra project operations and drives value to every part of your business.

Recent Comments